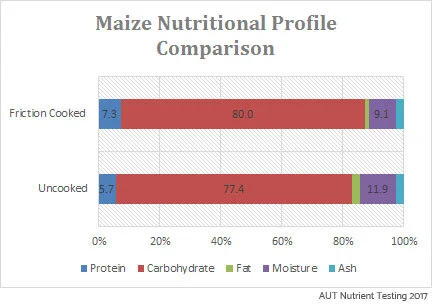

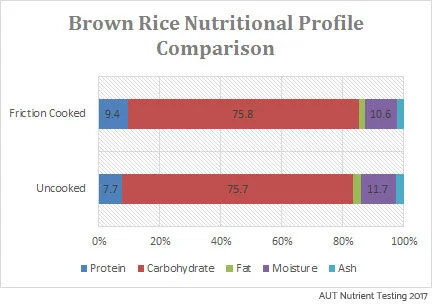

Friction cooking minimises the loss of macronutrients and improves their quality and digestibility compared to other food processing and cooking methods.

The effect on Protein, Carbohydrates, and Fats

No preconditioning

Some cooking processes precondition ingredients to improve how well the machinery runs and reduce wear and tear. This preconditioning can be responsible for the removal of important macronutrients.

Often the ingredients are preconditioned with steam to raise the moisture content to the correct level. This can cause the good oils and fats found in the ingredients to drain out.

The lower oil and fat content of the preconditioned mix leads to an increase in mechanical shear within the cooking machine when it is processed. Mechanical shear damages the structure of the carbohydrates, preventing the body from fully digesting and utilising macronutrients.

Steam preconditioning can also increase the chance of a Millard Reaction. This is a reaction between the carbohydrates and proteins that causes browning and undesirable flavours, along with a reduction in the amount of protein and carbohydrates in the finished product.

Removing the natural oils in the ingredients reduces flavour and has a negative effect on shelf life. To combat this some other food processing methods artificially add oils back into the product. This may be done just before the product exits the machine, preventing it from being fully cooked. Or a sugar-fat based spray may be used to coat the finished product to enhance its flavour. Both these methods have a negative impact on the nutritional quality of the finished food.

Friction cooking does not use any preconditioning. This prevents protein and carbohydrate loss from Millard Reactions, and the natural fats and oils in the ingredients are more likely retained. In addition to their nutritional benefits, the natural oils increase shelf life and flavour of the finished product. The fats and oils also reduce the impact of mechanical shear during processing, which prevents the carbohydrate structure from being impaired – allowing them to be better digested and utilised by the body.

No water or steam used in the cooking process

Water, usually in the form of steam, is often used to heat food, but it can have a negative impact on the nutritional quality of the finished product.

This addition of water or steam reduces the gelatinisation of starch in the product, therefore reducing the carbohydrate digestibility.

Water, coupled with the high temperatures used in cooking can result in the loss of lysine (an essential amino acid that is critical for tissue repair and the conversion of fatty acids into usable forms of energy in the body). High pressures generated during such cooking processes can cause the natural fats and oils that survived preconditioning to drain out.

Friction cooking does not use any additional water. This means carbohydrate digestibility is maximised, essential amino acids are retained and the loss of natural fats and oils is minimised.

Very short cooking time and low temperatures

Other processes take a long time and use a lot of heat to cook food. This exposes the product to a prolonged period of mechanical shear and high temperatures.

This has a significant effect on the protein quality of the finished product. The time being cooked at these high temperatures causes the primary protein structures to breakdown. This reduces protein digestibility and makes them unusable by the body.

Friction cooking is extremely rapid and uses lower temperatures to cook. This is enough to breakdown the complex secondary and tertiary protein structures for the body to easily digest and use, but not enough to affect the primary protein structures.