The possibilities are endless when it comes to utilising the ZAMPILL™ technology. We have helped many innovative companies and people turn their ideas into reality. Have a look through the case studies below to see how ZAPMILL™ is changing food production for the better.

WILD WHEAT

WILD WHEAT

Wild Wheat is a bakery that strives to deliver high quality, fresh and sustainable products daily. A problem they had was what to do with bread that just wasn’t fresh enough anymore. Enter the ZAPMILL™ Friction Cooker. By utilizing our innovative technology Wild Wheat is able to process their left over loaves into regenerated and exciting products. The initial product was the EcoLoaf, and we are working on some more exciting things to come. To learn more about the circular economy of sourdough, check out the video.

AUT

AUT

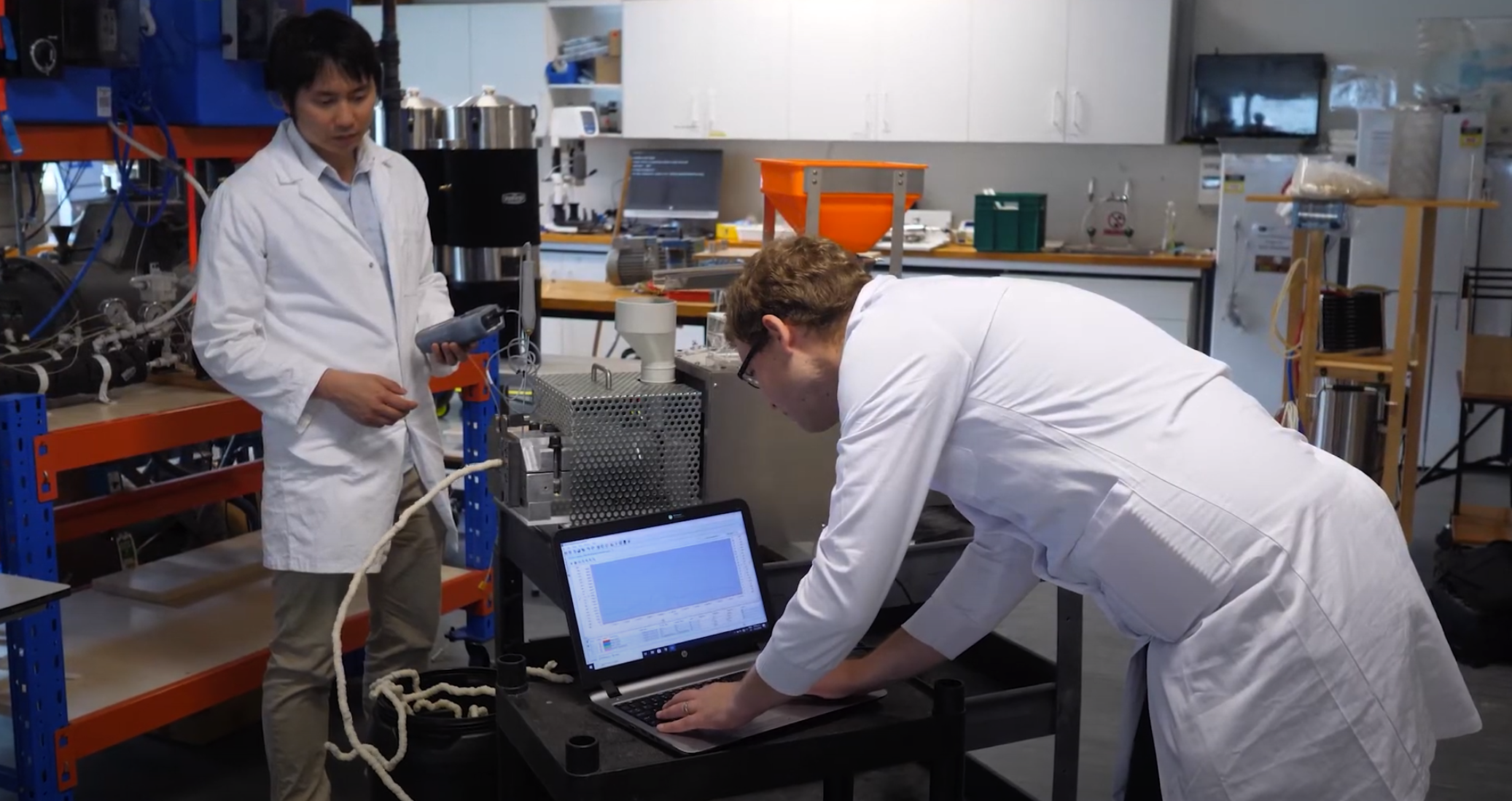

Auckland University of Technology (AUT) hosts one of New Zealand’s most prestigious Food Science Departments. They are always looking for new and innovative production systems, especially those which allow exploration into new ingredients. Dr Rothman Kam, a lecturer of Food Science at AUT took an interest in the ZAPMILL™ Friction Cooker and its ability to transform what could be otherwise considered food waste, into new and exciting food products. AUT are doing exciting things with our technology, with a specific focus on decreasing food waste and creating new circular economies of food. We look forward to seeing the outcomes.

University of Reading - United Kingdom

UNIVERSITY OF READING

The University of Reading is the base of one of the United Kingdom’s largest and highest ranked Food Processing Centres. A huge variety of research is based from this centre on the Whiteknights Campus and we were lucky enough to get involved. Dr Sameer Khalil Ghawi has a specific interest in advanced manufacturing systems for differing food products. Dr Ghawi took an interest in the ZAPMILL™ Friction Cooker and in 2019 we installed their first machine. We could never have guessed the products they would think to create, and we are looking forward to learning about even more applications for the ZAPMILL™ Friction Cooker.