ZAPMILL™ Friction Cooker’s size and unique friction cooking process makes it an extremely versatile and affordable machine for food production.

easy to use

ZAPMILL™ Friction Cooker is an easy machine to operate

Easily design and make your own products

The machine is tough, easy to maintain and clean

Built for continuous 24 hour use

In minutes you can switch from cooking one product to cooking another

cost efficient

ZAPMILL™ Friction Cooker uses less electric power than a domestic toaster

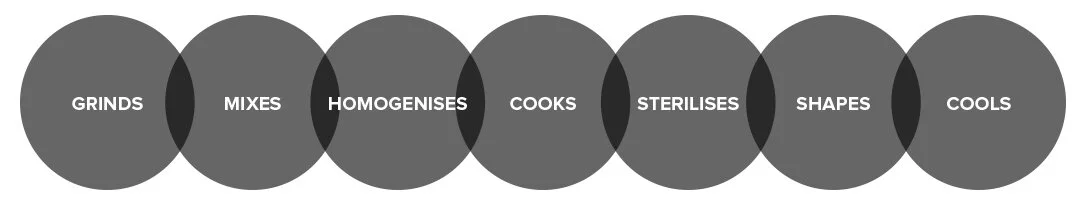

No grinders, No steam boilers, No driers, and No coolers are necessary

A simple production line can be set up to produce many types of food

Suitable for automatic production systems or manual operation

The machine does the whole job, except packaging

portable, go anywhere

ZAPMILL™ Friction Cooker is a “food factory in a box” ready to go where needed

Developed so it can be located near its source of raw materials

The module design allows for easy transportation

All it needs to cook is an electric power supply or a generator

small or large food production

ZAPMILL™ Friction Cooker can fit on a kitchen table to create an instant small cooking system

Or added to an existing operation to make new products and ingredients

Additional machines can be used as required to increase output

Each machine can cook a different product with one person operating a number of machines

End products can be shaped or made into crumbs, meal, or as sticks to suit the end user

You can view the technical specifications of the ZAPMILL™ Friction Cooker here